Exactly how to mount the Classicbond Rubber Roof covering membrane layer

Versatile EPDM (ethylene propylene diene monomer) roofing systems involve factory-made sheets that set irreversibly after heating for superb long-lasting resistance to weather. This roof was 3.5 x4.0 metres with a reasonably shallow roofing system incline. The roofing system was asymmetrical, the front cantilevered area was reasonably brief in contrast to the longer incline at the rear.

Any roof coverings that have not been examined in a while, now need to prior to the wintery fun impacts in. IT needs to be looked for any type of contraction, slits or rips, check parapet wall surfaces, corners, drains pipes and other areas that the EPDM rubber would have to develop around. Yeah, the rubber wedged between boards is a not so great detail. They additionally make a drip side you can take down and also cover the fascia and after that glue or fasten to that instead.

Establish the roof's actual surface by multiplying the two measurements after that separating the outcome by 42. The result will certainly provide you a harsh quote of the number of gallons you will certainly need for the whole Motor Home rubber roofing system covering application process. See to it to apply the coating in a location with proper air flow.

In this situation, the rubber roof covering might can be found in the kind of EPDM or TPO. You can make most repair services to keep your rubber roof with simple devices and materials without the requirement of sturdy tools.

When used in a Motor Home roof, you are ensured of its capability to look for into openings and fractures. Once dried, you will certainly also notice that it is a versatile, water tight, and rubberized covering designed to last for fairly a long period of time. It seals out water while also staying flexible and also pliable. Make note that just how the roofing finish will certainly function will certainly depend on what material is utilized in creating the topmost component of your Recreational Vehicle roofing.

Overlap both rubber membrane layers by 75mm (3inches).

Where roofing boundary ballast has been displaced by wind comb, include added larger size ballast (assuming the additional weight is enabled). Many codes call for 10 psf of # 3 or # 4 (nominally 1.5 in diameter) stone for the field of the roof covering, however you can upgrade to psf of larger stone (2 -.5 in diameter) in corners and borders. Additionally, you can make use of pavers in these important areas. A comprehensive document on making ballasted roofing systems for wind resistance is readily available on the SPRI site as ANSI/SPRI RP-4.

- It is additionally feasible to repaint the rubber roofing with an acrylic finishing.

- Besides the standard devices, such as a hammer to get rid of the old product, you will certainly additionally need a measuring tape, straight-cutting tin cuts to cut the new material, as well as a stonework little bit as well as mill.

- It has a lasting versatility while also with the ability of withstanding damages that could be triggered by freezing.

- As soon as dried out, you will additionally discover that it is an adaptable, watertight, as well as rubberized layer created to last for fairly a long time.

- The EPDM membrane layer that we provide will certainly be cut to specification to fit your roof, including the necessary overhang to guarantee very easy installation.

Normally other adhesives have trouble bonding to EPDM due to the high material http://https:/www.liveinternet.ru/users/patiusxjaj/post471654446/ of polyolefin substances in the EPDM. You'll intend to check your rubber shingles a couple of times a year, and the simplest method to do that is by keeping it tidy. Cleansing your roofing 3-4 times a year can additionally assist you preserve your warranty. To clean your roof yourself, start by sweeping or rinsing off as much loosened crud as possible. Then making use of a spray device, apply an industrial quality cleanser particular for rubber care.

A T-joint, where 3 layers of membrane layer come together, is particularly susceptible to moisture penetration. For older EPDM roof covering systems, a target piece of self-adhering membrane layer can be centered over the T gap during renovations to the EPDM membrane. Elastomeric roof based upon ethylene propylene diene terpolymer (EPDM) has actually been around for more than four decades as well as can assert 500,000 required roofings consisting of 20 billion square feet in place. Black EPDM is very resistant to UV and also ozone as well as has exceptional sustainability and life. White on black EPDM is cooler as well as extra power reliable yet has a shorter life than black EPDM.

It appropriates for those who are preparing to do a solitary application or two coverings and also make a decision whether another product will certainly benefit their needs following time. One benefit of this rubber roof covering is that it is UV-resistant. It is additionally reliable in securing your RV's roof covering from the natural environments.

How is EPDM installed?

In general, you should expect the EPDM roofing cost to be between $2.50 and $5.00 per square foot. For an average-sized roof of 1,500 square feet, that's a total cost of around $4,000 to $8,000. Installing EPDM roofing on a small area, because it involves more detailed work, might cost up to $10 per square foot.

The edges of my rubber roof can be seen from the ground, as well as don't look excellent when they obtain filthy. What can I do around this?

Does EPDM shrink?

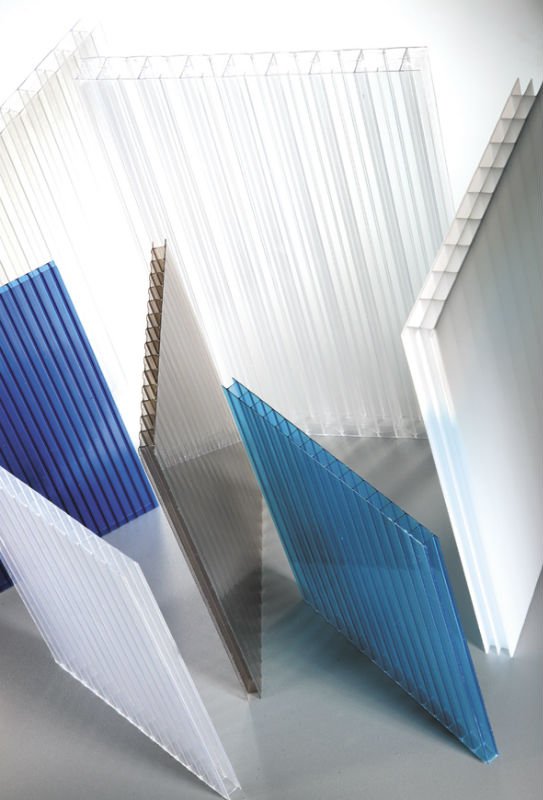

Thermoplastic materials can be joined together (usually by heat welding), unlike elastomers, which cannot be heat welded. EPDM combines two thermoplastics, ethylene and propylene, with a diene that permits the ethylene-propylene chains to be crosslinked.

Not just does it take very little power to construct this material, but the roofings last nearly permanently, as well as when they do require changing they are practically 100% recyclable. They are nearly difficult to ignite, and also they can really hinder the development of a fire. House owners below in the Northeast are encouraged to speak with the roof covering experts at United House Experts if expense is a factor.